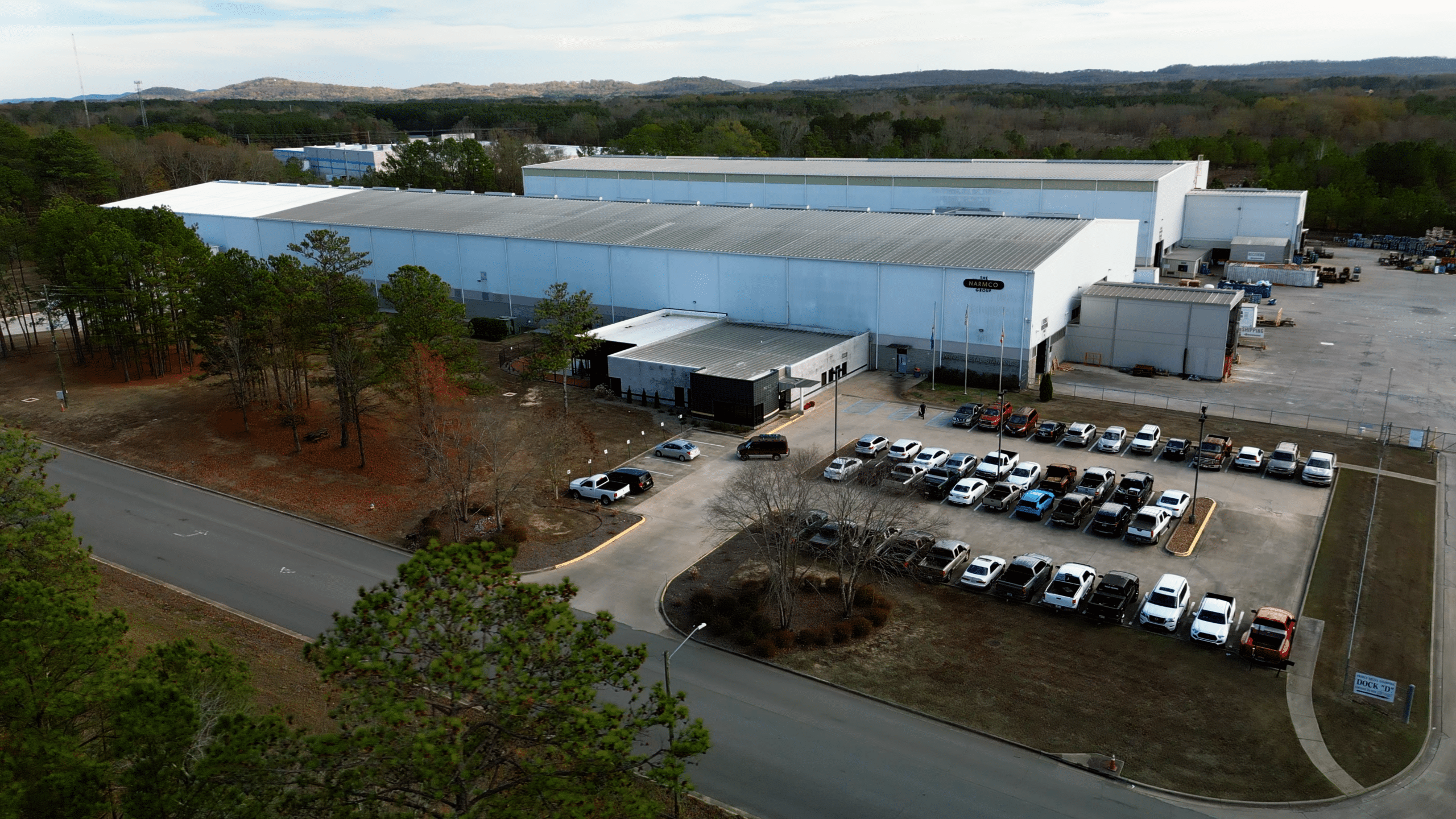

Metal Stamping

Prince Metal Stampings is a leader in metal stampings for the automotive industry. We specialize in progressive stamping with presses from 400T to 2500T, Transfer presses up to 3500T, and Tandem line stamping on five press tandem lines from 500T to 2300T.

Prince Metal specializes in under body components such as structural pillars, wheel wells, shock towers, window apertures, and floor pans along with various small bracketry.

With bed sizes up to 240” X 108” and our variety of stampings processes/tonnage we, can accommodate any automotive cold stamping need. Many of our stamping processes are also complemented with robotic material handling.

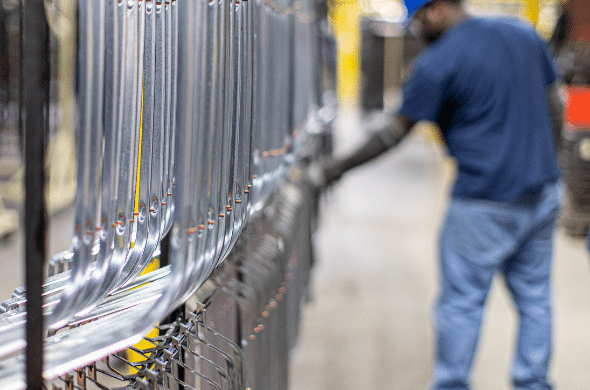

Welded Assembly

Prince Metal Stampings uses a variety of six axis robots to assemble many of the parts we stamp. The joining processes these robots perform include resistance welding, mig welding, structural glue application, and sealer application.

Our assembly cells will incorporate several robots (both material handling and joining) working together to assemble parts such as side walls, wheelhouses, roof assemblies, and other complex under body assemblies.

Electro Coating

Prince Metal Stampings has a dedicated in-house Electrocoating processing line capable of processing 500 SQ.FT. of HIGH EDGE E-COAT per cycle. This square transfer system utilizes 9 pretreatment stations, followed by paint and 3 post rinse stations.